Written by: VEDAT ÖRÜÇ

Translation: Sebla Küçük

Çöpler Gold Mine, located in Çöpler village in İliç district in Erzincan, produces gold by using cyanide leaching method [a technique that uses cyanide to dissolve and extract gold from heaps of soil]. The mine will now increase its capacity for the second time after the Ministry of Environment, Urbanization and Climate Change approved the Environmental Impact Assessment (EIA) report on October 7, 2021. The 20-year-old mine has been destroying ecological environment and killing wildlife in the area. Locals have been suffering from severe health disorders, including asthma, bronchitis and cancer, due to mining activities. In Sabırlı and Yakuplu villages, residents have given up breeding livestock, which was once their primary livelihood.

WILL THEY WAIT UNTIL A DISASTER HITS THE AREA?

On November 18, something terrible happened in Turkey: an explosion took place at the waste storage facility of a mine owned by Nesko Madencilik in Şebinkarahisar district of Giresun, which resulted in the contamination of a river near the facility. The river carried the waste from the mine to Kılıçkaya Dam, which supplies water for irrigation of the farmlands in the area. The disaster caused major contamination in the agricultural areas and water resources in the region. The company had to indefinitely suspend its operations for leaking uncontrolled wastewaters into the environment.

However, it was later understood that the company had filed an application to the Ministry for a fourth capacity increase only a few days before the disaster. If the tailings dam hadn’t failed and the public hadn’t found out what happened there, the Ministry would probably approve the application, which would likely result in an even bigger disaster. A similar incident happened at the same mine in 2018, killing eight million fish, but officials successfully swept it under the rug and the company got away by paying only a small amount of money as administrative fine.

What happened in Giresun is not a rare incident in Turkey. In 2011, at Eti Gümüş mine in Kütahya, waste tailings impoundment failed due to heavy rain, and thousands of cubic meters of toxic waste leaked into the nature. There were reports of deaths due to arsenic and cyanide contamination in the area after the disaster. İzmir Regional Directorate of Sanitation analyzed the samples from supply water network collected in the area, and found that the samples contained 44.24 mg/l cyanide, which was 221 times higher than the permissible value. Environmental organizations and trade unions filed criminal complaints against those responsible for the disaster, but the court passed only small sentences: four officials from the mining company were sentenced to 1 year 10 months of imprisonment while one defendant was acquitted. All sentences were suspended.

NEW DISASTERS LOOM

As Turkey lacks environmental regulations or other legislation to ensure effective oversight over mines, new disasters loom. One of the risky sites is the Çöpler mine pit, which has the potential to be the biggest cyanide mine in Europe and Turkey. The company owning the mine plans to boost capacity for the second time, despite recent disasters across the country.

In Turkey, forests and pastures are protected under article 169 of the Constitution, which says “Acts and actions that might damage forests shall not be permitted.” However, the amendment dated April 26, 2004 has led to dramatic changes in the Law on Mining. Many argue that the country has since been handed over to mining companies. This was followed by other amendments in the Directive of Permits for Mining Activities in 2005, 2009 and 2017, which expanded the scope of the law. With these changes, forests, pastures, protected areas, water basins and contiguous areas were opened for mining activities.

However, the amended directives didn’t cover “areas under private ownership.” Following the changes in the Law on Mining and the directives, Anagold mining company got the green light for its EIA in 2008 for Çöpler mine facility, which was planned to be built in İliç district in Erzincan. According to the EIA report, the project area consisted of public lands, forests, pastures and privately-owned lands. The authorities were able to turn forests and pastures into mining sites under the recently amended directives, but they still had to convince private owners. Anagold, eager to extract tons of gold in İliç without any backlash from locals, found an unprecedented method to solve potential problems.

CASH ASSISTANCE FOR PEASANTS, PERSUASION AGREEMENTS

The first method adopted by Anagold was organizing best practice trips abroad – a method that is commonly used in various mining and energy projects in Turkey. The idea is convincing residents of the area and local authorities by demonstrating them the best practices. For example, if there is a plan to build a thermal power plant, the investing company takes mukhtars (elected leaders of villages) and the community leaders to a similar facility in Western Europe and demonstrates them these systems are actually clean energy-generation systems. The trip, of course, covers some touristic itineraries, with accommodation at luxury hotels and meals at fancy restaurants, all of which make sure that the participants are happy when they go back to Turkey. The company officials hope that these trips will undermine the potential resistance against energy projects.

Anagold also organized similar trips even before the construction was started in İliç.

Members of the community in İliç, including mukhtars, peasants, district governor, mayor, political party leaders and bureaucrats from several villages were taken on a trip to mining facilities in Colorado and Nevada in the U.S. Photo credit: A3 Haber

Members of the community in İliç, including mukhtars, peasants, district governor, mayor, political party leaders and bureaucrats from several villages were taken on a trip to mining facilities in Colorado and Nevada in the U.S. Photo credit: A3 Haber

Starting in 2005, opinion leaders in the community were taken on trips to mining facilities in the U.S. There were three trips in total. The first group consisted of 18 people, including mukhtars and peasants from Çöpler, Sabırlı, Dostal and Bağıştaş villages as well as the district governor and the mayor of İliç, political party leaders, executive assistant of the governor of Erzincan and deputy director of special provincial administration. The group flew to the U.S. on October 15, 2005 and participated in technical and touristic visits to mining facilities in Colorado and Nevada during the 10-day program.

Members of the local community, opinion leaders and bureaucrats in Erzincan were taken to a second trip to the mining facilities in the U.S. in 2006. Photo credit: Mynet

Members of the local community, opinion leaders and bureaucrats in Erzincan were taken to a second trip to the mining facilities in the U.S. in 2006. Photo credit: Mynet

The second delegation to visit the U.S. included AKP MPs in Erzincan, mayor of Mercan representing Erzincan Union of Municipalities, head of Erzincan Chamber of Trade and Industry, head of the provincial municipal assembly and the chief of police in Erzincan. The third and last group arrived in the U.S. on September 17, 2006, and members of the delegation included mayors of Erzincan and Kemaliye, director of Aras electricity distribution company, two local reporters from Erzincan and two mining experts. However, locals claim that the members of these delegations spent most of their times at five-star hotels instead of visiting mining facilities. According to İlhan Poyraz, assistant to general manager of Çukurdere Mining company (a partnership run by Anagold), the total cost of the trip was approximately 205,000 USD. The three groups stayed at five-star hotels, and mostly visited touristic sites and went on shopping in Nevada and Chicago.

Süleyman Duygun, who was in one of these groups, described his trip to the U.S. in an interview with Özer Akdemir in 2013: “The mining facilities were too far from residential areas. There were other facilities near residential areas but nobody lived in those places. When I asked why, they didn’t answer my question. Two days after we came back, the public relations manager of the company tried to get us to sign a document to verify our trip. The paper said we went to the U.S. and visited mining facilities that use cyanide for extracting gold, and that cyanide didn’t cause any damage on the nature, animals or human beings. I refused to sign it because I didn’t know anything about cyanide. Other strange things also happened after that trip. Some opinion leaders in this area who owned land found jobs in the mining company. Politicians who opposed to construction of the mining facility turned into advocates of the company. Even the district governor held a meeting with mukhtars and tried to create a positive perception about the project.”

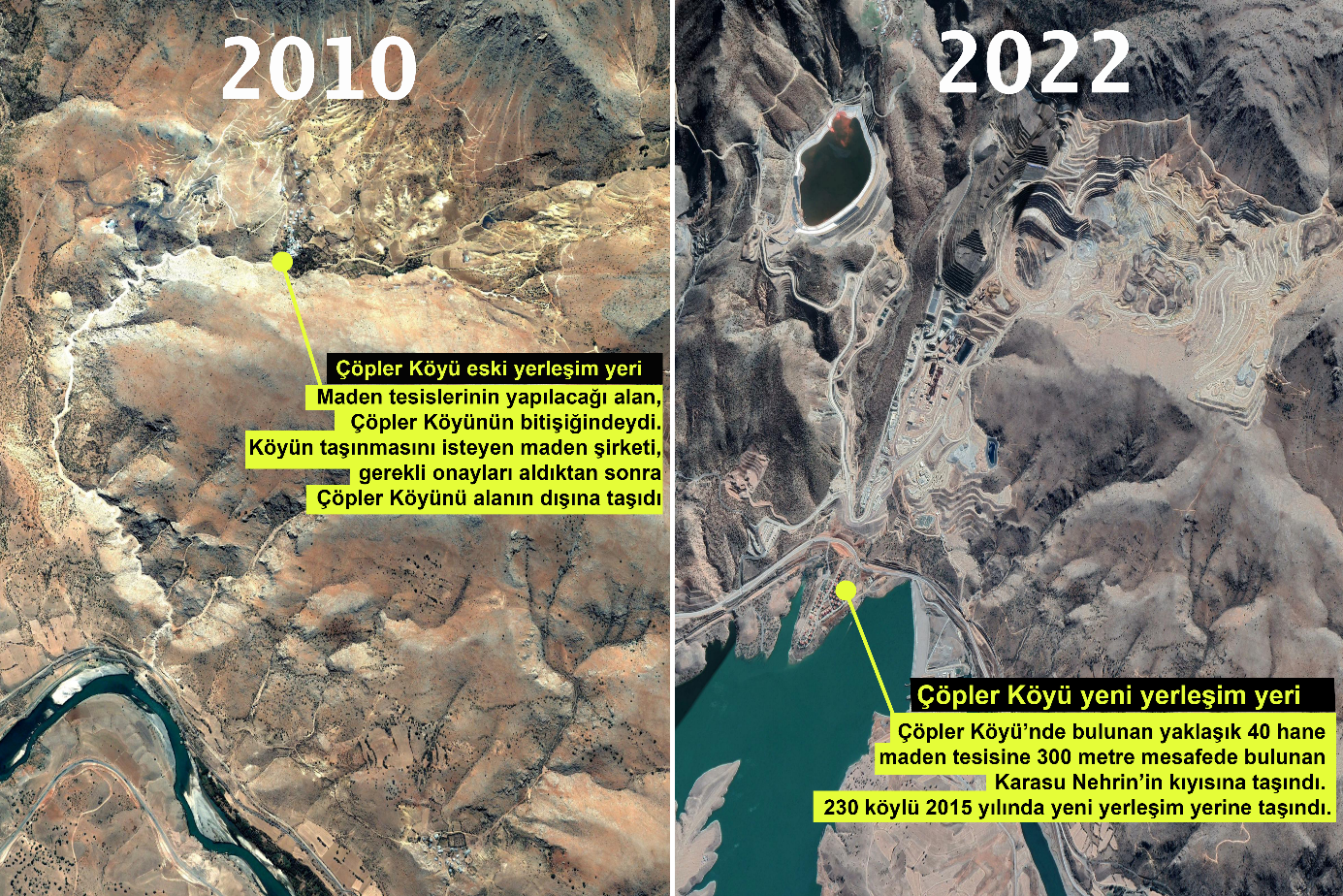

When these persuasion trips fell short of mitigating backlash from locals, Anagold understood that it had to spend some money. The company paid big sums to buy farmlands owned by peasants which were in the project area. Back then, the price of a decare of farmland was about 2,000 TRY. Anagold accepted to pay sums that were several times higher than the fair value – it paid approximately 5,000 or 6,000 TRY per decare of land. However, buying all farmlands wasn’t enough. Anagold also wanted the farmers to evacuate the village. About 40 houses in Çöpler village were moved to the banks of Karasu river. 230 residents were settled in the new location in 2015.

View of Sabırlı village before and after the project.

View of Sabırlı village before and after the project.

The site of the planned mining facility was adjacent to Çöpler village. The mining company, after obtaining necessary permits, moved the village to approximately 250 meters away from the project area. The company built 40 duplex houses for 40 families. This was the “second migration” for the majority of the villagers because members of Şafak family from Elazığ province had to move to Erzincan in 1968 after their village was flooded by Keban Dam. Çöpler village became their second home, but now they had to move again, this time because of a mine project.

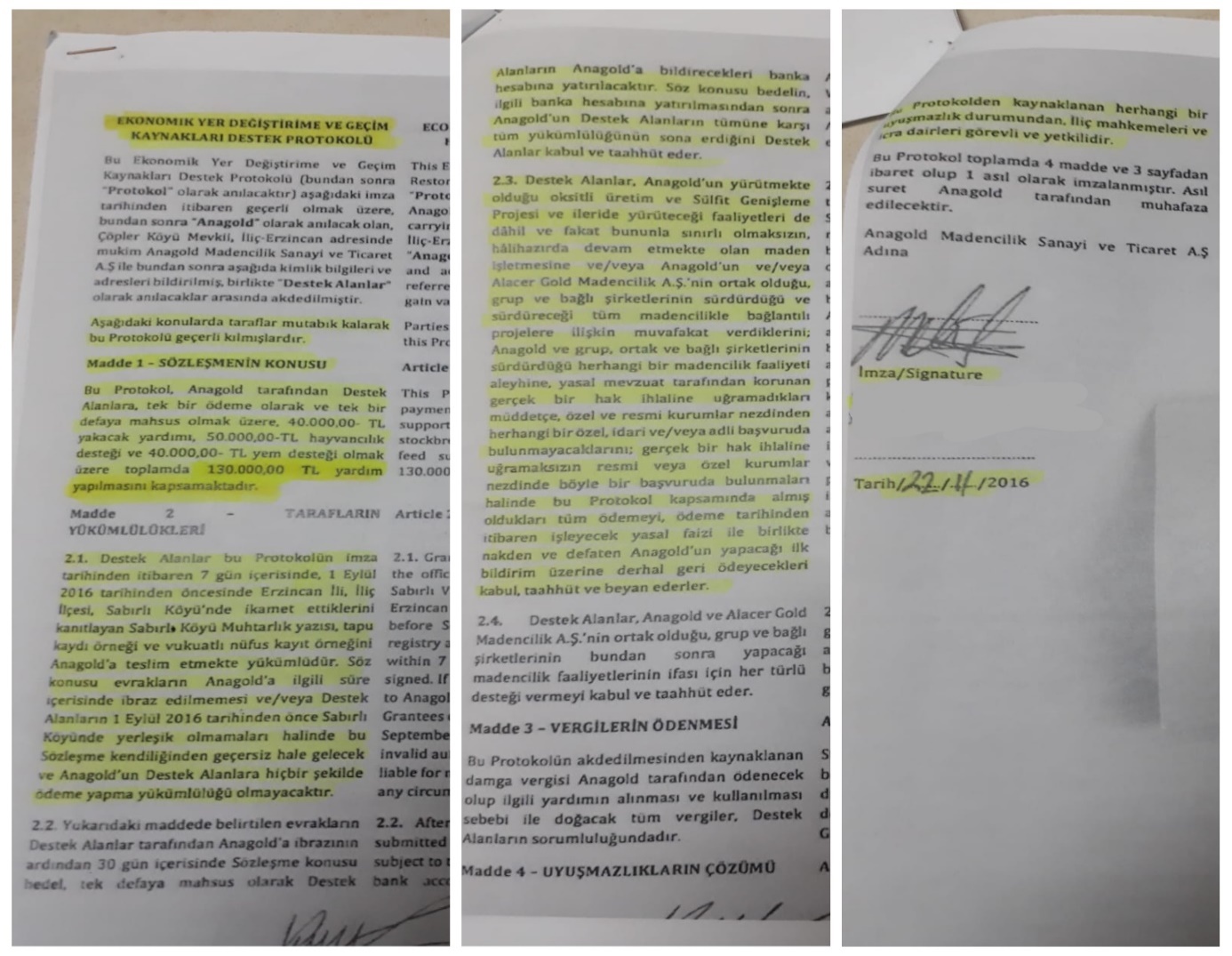

Anagold’s generosity also reached out to residents of Sabırlı village. The company signed Economic Relocation and Livelihood Support Protocols with the residents, who, upon warranting that they will consent to the mine project and will not go to the court, received 130,000 TRY from Anagold.

Copy of the protocol executed between residents and Anagold

Copy of the protocol executed between residents and Anagold

The protocol says, “the residents who received assistance have given their consent for the mining projects implemented now and/or to be implemented in the future by Anagold and Alacer Gold Maden AŞ [which was later renamed as SSR Mining], their group companies or affiliates. Those who have received assistance shall not make any administrative, private and/or legal claims unless there is an actual violation of their rights. Otherwise, the company shall be entitled to request repayment of the cash assistance, which is 130,000 TRY, with interest.”

Trips to the U.S. was not the only expense budget Anagold had on its balance sheet. In an attempt to build a good reputation, the company became the sponsor of Erzincan University in 2019, and built a laboratory for the engineering faculty. Anagold also became one of the sponsors of Erzincanspor football club in 2014, and the club was renamed as Anagold24 Erzincanspor from 2014 to 2021. The company signed a protocol with the governor and district governor of Erzincan to build a primary school with 16 classrooms in İliç. According to the information on the website of the mining facility, the company spent approximately 5 million TRY for these projects.

MINES USE “HIT-AND-RUN” TACTIC

Indeed, locals have a history with mining companies as small mines have been operating in the area for a long time. However, according to villagers, the majority of these mines use “hit-and-run” tactic. Companies go to a village, dig out the ore and leave Erzincan with a big debt. This is why many tend to think twice when they deal with mining companies.

Reports say residents initially cold-shouldered Anagold; however, the company executives successfully turned the economic woes of the locals into an opportunity: residents who make a living from livestock breeding and farming had been bleeding money because of the government’s policies that forced farmers to rely on loans. Many were on the brink of quitting – they were in debt, and they were not able to pay back even if they sold all of their livestock. Imports of livestock had taken a toll on farmers in the area. Their livestock as well as their produce, such as milk and cheese, were sold at very low prices. Many breeders were struggling to keep their business running while others had already gone bankrupt. Then came Canadian Anagold and its partner, Çalık Holding. At first, they ladled out the money. A former livestock breeder said, “They paid 500 TRY for something which would only cost 5 TRY. They salted the mine. The gold mine with its cyanide was labeled as the only way out for the people here.” As locals didn’t have any other choice, they couldn’t resist.

CHAMELEON TACTIC: OWNERSHIP CHANGES HANDS EVERY FEW YEARS

Rio Tinto, Anatolia Minerals, Çukurdere Madencilik, Alacer, Anagold, Lidya Madencilik, Çalık Holding, Avoca Resources and SSR Mining… These are the names of the companies which are official operators of Çöpler mine facility. The name of the operator changes every few years or shares of the operator change hands as if something is hidden. The first efforts for prospecting ore in 1999 were launched by a partnership between Rio Tinto and Çukurdere Madencilik, the Turkey-based affiliate of Denver-based Anatolia Minerals Development Limited.

Rio Tinto does not have a very good reputation. Gasberg mine, which is the largest gold mine in the world, released 125,000 tons of toxic waste into Ajikwa River every year, and therefore there is now a dramatic environmental pollution in Papua New Guinea. Rio Tinto is one of the partners at Gasberg. The mine caused major contamination of waters, fish, humans and soil, and as all farming activities have been suspended, the area suffers from famine, which has killed and is still killing hundreds of people.

The activities at Çöpler mine were undertaken by Çukurdere Madencilik, which was the holder of the operating license for the facility. In 2009, which is one year before the mine became operational, Çalık Holding, a close ally of the Turkish government, bought 20 percent of the shares of Çöpler mine, and the consortium operating the facility was renamed as Anagold. That is, the mine was turned into a facility owned by Anagold Madencilik, a partnership between Anatolia Minerals and Lidya company. On February 18, 2011, Anatolia Minerals merged with Avoca Resources, the third biggest manufacturer of gold in Australia, and the merger created Alacer Gold. Alacer Gold mainly operated in Turkey and Australia, and the company’s stocks were traded in Australian and Canadian stock markets. In May 2020, Alacer Gold merged with SSR Mining, another Canada-based company, and thus the partner of Çöpler mining facility was changed again. SSR Mining is actually a 70-year-old company, but it has a new name. The company formerly operated in silver mining under the name “Silver Standard Resources” (SSR), but changed its name to SSR Mining on August 1, 2017.

HOW DID THE MINE TURN INTO A CHEMICAL PIT?

Cyanide easily combines with many metals, which makes it useful for separating metals like gold from their ore. Cyanide is widely used in the mining industry because of its efficiency and low costs. The chemicalization process at Çöpler gold mine first started with the use of cyanide leaching in sulfide ore. In 2008, Anagold obtained the EIA approval for its sulfide facility project, where sulfide ore would be processed using cyanide leaching method. Thus, the company got the green light to use cyanide in Çöpler.

The company spent 660 million USD to build the sulfide facility, which was completed in 2014, and drafted a new EIA report to boost the capacity of the mine pit. The report contained the list of chemicals to be used in the mine pit as well as a table showing the amounts to be used. According to this table, the company was planning to use 6,500 tons of cyanide, 8,900 tons of sulfuric acid, 410 tons of nitric acid and tons of silica and glycerin per year. In other words, the whole area would be turned into a chemical hell. Before long, the company got the permission to increase its capacity.

Before and after the first capacity increase

Before and after the first capacity increase

According to the final EIA report, the activities at the mine pit will continue for 16 years. This means 1,720,000 tons of toxic waste will be released into the nature. However, the owners of the mine pit changed before this deadline. In 2020, Alacer Gold merged with Canada-based SSR Mining, and the first action of the new management was to increase the capacity of the mine once again.

The company, which had melted Munzur Mountains into gold, was ambitious about inundating the area with toxic chemicals. The owners continued with an aggressive growth strategy at the open-pit mine, with new EIA reports that were hastily approved by authorities. In just 13 years, the mining site expanded by 2.5 times, covering an area that is equal to 2,447 football fields. The EIA report for the second capacity increase was approved on October 7, 2021. With this move, which will cost 1,162,800 TRY, the project will become the biggest gold mine in Turkey and Europe.

With the second capacity increase, the amount of sulfuric acid to be used in the mine will go up from 9,000 tons to 122,000 tons per year. Furthermore, the amount of cyanide to be used will reach 11,000 tons per year. In addition to cyanide and sulfuric acid, the facility will use 16 hazardous chemicals, including 1,050 tons of nitric acid per year.

Tailings impoundment site at Çöpler mine facility, which has a surface area that is equal to 197 football fields

Tailings impoundment site at Çöpler mine facility, which has a surface area that is equal to 197 football fields

With the hike in amount of chemicals used at the facility, the amount of waste will also go up. According to the EIA report, the company will build 10 evaporators, which will vaporize toxic substances in tailings impoundments and release them into the air. Besides, the total area of the mine facility will be expanded with a new flotation (mineral processing) facility and a new waste tailings facility. A second tailings impoundment will also be built because the first one – with an area of 197 football fields – reached its full capacity earlier than expected as the mine produces 6 tons of operational waste per day.

With this expansion, the total area of the mine facility will reach 1,747 hectares, including 783.72 hectares of forest, and 95.93 hectares of pasture. The mine will be located near Bahçe, Çöpler and Sabırlı villages, and will be at 120 kilometers to Erzincan, on the west of the city center, and at 850 meters to İliç district. With the capacity increase, the distance between Euphrates river and the mine will be only 300 meters. And the mine will be located at 250 meters to the nearest residential area, i.e. to Sabırlı village and the new location of Çöpler village.

RISK OF ACCIDENTS AND FATALITIES AT THE MINE

Upon a request from Sedat Cezayirlioğlu, a resident of Sabırlı village, the Turkish Thoracic Association reviewed the EIA report published by the company for capacity increase application. The association, in its report signed by Prof. Metin Akgün, concluded that almost all of the chemicals to be used at the facility have significant negative effects on human health and the environment. The report said the majority of these substances lead to damages in the skin, the eyes and the digestive system, and inhalation of their fumes may result in damages in the lungs. According to the report, sulfuric acid may cause severe burns in the respiratory system, the eyes and on the skin, which may also be caused by exposure to sodium cyanide, nitric acid, sodium hydroxide and other chemicals.

Prof. Akgün also refers to the “risk of leakage or failure of waste storage area or risk of contamination of ground waters with rainfall washing waste substances into the ground.” Besides, the report emphasizes that “the dust to be created by a potential explosion may pose health risks for the respiratory system and lungs.” The report shares the following conclusions: “Even if it is assumed that there will not be any risks during the operation of the facility, the risk will exist perpetually as the waste products cannot be completely eliminated after the facility ends its operations. The total tailings area in the facility is 788,386 m2 – i.e., the tailings capacity is equal to the total distance of a return trip between Ankara and Istanbul via a highway that is one meter wide. Considering that the site is very close to the Euphrates River, a potential leakage or failure may lead to a dramatic environmental disaster. The substances to be used will inevitably lead to pollution of the soil, waters and air. The site is also very close active fault lines and water resources that run into Euphrates River, which means a potential accident/disaster may affect the whole area and ecosystem in the Euphrates basin.” Prof. Akgün also warns against the use of acids and cyanide solutions in the same area: “The slightest ignorance or lack of attention may lead to an irreparable disaster.”

According to Turkey’s Seismic Map for Erzincan published in 1996 by the General Directorate of Natural Disasters, Department of Seismic Research, facility is in a second-degree seismic zone. Potential tremors in the area may lead to contamination of Euphrates River with chemicals in tailings. Or a flood that may be caused by extreme weather events, as a result of climate change, may carry tailings into Euphrates River. If what happened in Şebinkarahisar happens in tailings of Çöpler mine facility, the vast geographical reach of Euphrates River will mean that the disaster may affect a larger area, which is a frightening scenario for residents of İliç.

WHERE DO HUNDREDS OF TONS OF SULFURIC ACID COME FROM?

The EIA report says sulfuric acid is procured from TEKKİM chemical company in Bursa. The public is familiar with the name of the company due to the claims that Syrian opposition forces were using TEKKİM products to build improvised explosives in Syria. It is also reported that some sulfuric acid is supplied by Eti Bakır facility in Samsun, which is owned by Cengiz Holding. The facility produces 420,000 tons of sulfuric acid per year, the majority of which is transported to Çöpler mining facility.

The numbers for annual chemical consumption given in the EIA report for Çöpler mine demonstrate that the facility uses approximately 30,000 tons of sulfuric acid per day. This means 30,000 tons of sulfuric acid transported from Bursa or Samsun to Erzincan on daily basis. These hazardous chemicals travel 1087 kilometers from Bursa or 451 kilometers from Samsun and arrive in İliç. As cyanide and sulfuric acid are highly hazardous substances, they have to be transported under strict precautions and accompanied by escort vehicles. Traffic patrols on the transportation route have to be informed in advance about the freight. However, even if chemical tankers are strictly regulated, accidents involving these vehicles pose significant risks for İliç and other residential areas on the route.

In 2018, a chemical tanker transporting sulfuric acid to Çöpler mine facility overturned near the natural spring water fountain on İliç square

In 2018, a chemical tanker transporting sulfuric acid to Çöpler mine facility overturned near the natural spring water fountain on İliç square

On October 24, 2018, a chemical tanker truck transporting sulfuric acid to Çöpler mine facility was driving through central part of İliç although it was a violation of the regulations. As the truck was passing through the central square of the district, its drain hose went off and the contents of the tanker spilled all over the streets of İliç. The water supply network was only five meters away from the scene. The incident, which could have led to a major disaster, required emergency response from expert teams. However, locals said municipality teams arrived at the scene hours after the accident, and merely washed the streets with water cannons.

Unfortunately, this was not the only accident that happened in central İliç. On June 6, 2019, another tanker truck transporting sulfuric acid to the mine flipped over at the junction of the roads to Kuruçay and Kemah near İliç, spilling 30 tons of sulfuric acid. According to procedures, the area was supposed to be quarantined; however, authorities merely covered the affected area with soil and swept the whole incident under the rug.

Soon after this accident, another similar incident in Çöpler mine facility was reported by media on June 26, 2019. A worker, named Mehmet Can, was severely injured after sulfuric acid was spilled on his feet. There were allegations that officials at the mine tried to treat Can with some creams, and sent him to see a doctor five days later because their creams didn’t work. After a while, he was laid off.

“HIKE IN INCIDENCE OF ASTHMA, BRONCHITIS AND CANCERS”

Eşref Demir, Sedat Cezayirlioğlu and Nuri Uyar. These three men are villagers who have been resisting against the mine project for 20 years. Eşref Demir and Sedat Cezayirlioğlu are from Sabırlı village which is located at 250 meters to the toxic waste tailings site, and Nuri Uyar is from Yakuplu village, which is adjacent to Çakmaktepe Mine Pit, the site of the ore storage facility. The men say the area has been caught in a clamp because of the project: mining companies have been illegally imposing plans on residents, forcing them to migrate. The ecological damage caused by the mining facility leads to an increase in health problems.

Sedat Cezayirlioğlu said the incidence of asthma and lung cancer has increased recently: “This facility has already created unprecedented damages. They are using some chemicals which are much more hazardous than cyanide. Incidences of asthma, lung cancer and bowel cancer have increased. Babies are born with birth defects. People are poisoned to death because of cyanide. Many mine workers have asthma. Apiculture in this area is dead – beehives are empty. Local agriculture industry is dead. All livestock breeders have become mine workers. The mine is expanding day by day, almost swallowing up the whole area. The tailings impoundment was supposed to fill up in 25 years, but now it’s reached its full capacity in only two years, and they are increasing capacity. The tailings dam will expand to a size that is equal to 650 football fields. Euphrates River is only 350 meters away. The chemicals here will be spilled all over the region in the event of a minor incident, and it will affect the whole country, creating an unavertable disaster. The tailings dam has been built on an active fault line. The sulfuric acid and cyanide in the tailings dam will be released into the atmosphere. We are selling out the future of our children to the U.S. The whole area has already been turned into Chernobyl.”

The mine workers we interviewed also confirmed Cezayirlioğlu’s account. A worker at the gold-casting and gold-stripping area said he was exposed to leaked ammonia for three years. One day he fell it and was taken to the hospital. Although he had no history of a chronic disease, he was diagnosed with asthma. He received a health report from Ankara Atatürk Hospital of Thoracic Diseases, Clinic for Vocational Diseases, but the mine company refused to change his department and he was exposed to more gas leak. He became ill again and started receiving treatment for his condition but this time he was laid off by his employer. He went to court to make a reinstatement claim, and when experts analyzed his former working conditions, it was revealed that he was exposed to ammonia.

Another worker we interviewed also confirmed that the working conditions were not in line with workplace safety regulations, and that workers often get sick due to poor protective equipment. Particularly the digger operators of in the ore extraction area work without any precautions against dusting, and therefore they inhale dust containing minerals and suffer from respiratory diseases. According to workers, the most common health condition among the workers is the pulmonary disorders, such as asthma, due to inhalation of dust, followed by hearing disorders caused by high levels of noise. Furthermore, workers don’t undergo any medical screening unless they get sick, so it’s often too late when they are diagnosed with a chronic disease. So, they continue to work in a dusty atmosphere, marching towards death every day.

MINE PROJECT UNDERMINES AGRICULTURE AND LIVESTOCK BREEDING, KILLS WILDLIFE

The second capacity increase at Çöpler Mine covers 80,32 hectares of agricultural land. The majority of the farmlands in the region were bought by Anagold. And, under the Directive on Preservation and Use of Agricultural Lands, the company obtained necessary permits to use these lands for non-agricultural purposes. The arable lands in the region are already limited because of the steep and uneven terrain. In other words, the mine has occupied a significant portion of the lands that can be cultivated.

The major livelihood sources of the area are agriculture, livestock breeding and beekeeping. According to the Turkish Statistical Institute (TUİK), the district produced 130 tons of natural honey in 2019. In agriculture, farmers in İliç produced 120 tons of grapes, 600 tons of apples and 234 tons of pears. Livestock figures are less promising. According to TUİK’s data for the year 2020, there were 2,387 large and 572,600 small cattle in the region versus 2,308 large and 552,600 small cattle in 2004. This comparison with the numbers from 16 years ago shows that the livestock industry in the region hasn’t seen a significant improvement throughout the years.

Agriculture and livestock breeding are still the major livelihood sources in the area, but today these two industries are at risk due to Çöpler mine. Although some argue that the facility is the biggest creator of jobs in the region, the employment capacity of the mine can support only a small number of people. As of March 2019, the mine employs 2,168 people (including 668 people directly employed at Anagold, and 1,500 people in subcontractor companies). 715 out of these 2,168 employees are from İliç and nearby villages. This means that in this district which is home to approximately 9,000 people, agriculture and livestock breeding are the major sources of income for the locals.

The former mukhtar of Sabırlı village, Hüseyin Yıldırım, says the mine is threatening the livelihoods in the district: “Before the mine project, locals were breeding animals or growing crops. But after the project was launched, people gave up their livestock and ran to work at the mine. Nobody is breeding animals now. Those who have a few cattle hire Afghan shepherds. As we don’t have any farmers any more, we rely on imports to supply barley and hay. But the cost of these imports is very high, so the locals have given up livestock breeding. Nobody produces yoghurt any more. If they shut down the mine tomorrow, those who have a fancy lifestyle will starve. I mean, if they shut down the mine, everything would just collapse. Unfortunately, the villagers are now dependent on the mine.” The former mukhtar’s account reminds us the stories we heard about mines in another area: The mine comes, transforms the locals and leaves behind only a wreck.

Erzincan is famous for its oak honey. Therefore, one out of every three people who have livestock also has beehives. Nuri Uyar, from Yakuplu village in İliç, has been a beekeeper since he was 13. Uyar also fights against the damage created by the mine because his bees have also suffered from the environmental impact of the project. Uyar had 150 beehives but one morning he woke up to see all of his bees were dead. Uyar, who had never seen something like this before, suspects that what killed his bees was the dust coming from the mine pit: “Evaporation of the chemicals in the mine and the dust coming from the pit killed my bees. I have been a beekeeper since I was 13 and this is the first time that I saw bees dying because of dust. Normally, dust doesn’t kill bees – it only reduces the yield. The chemicals are killing the bees. And normally bees die out there, in nature – they don’t die in the hives. I found all of my bees dead inside the hives. Imagine – how can human beings live in an area where even the bees can’t survive?”

MINE PIT GRADUALLY DEVOURS THE WHOLE EUPHRATES BASIN

As forests, pastures, agricultural lands and even residential areas are easily given up for mine projects and companies try to tap more and more into natural resources due to the worsening economic crisis, one can’t help but feel more pessimistic about the future of Euphrates basin.

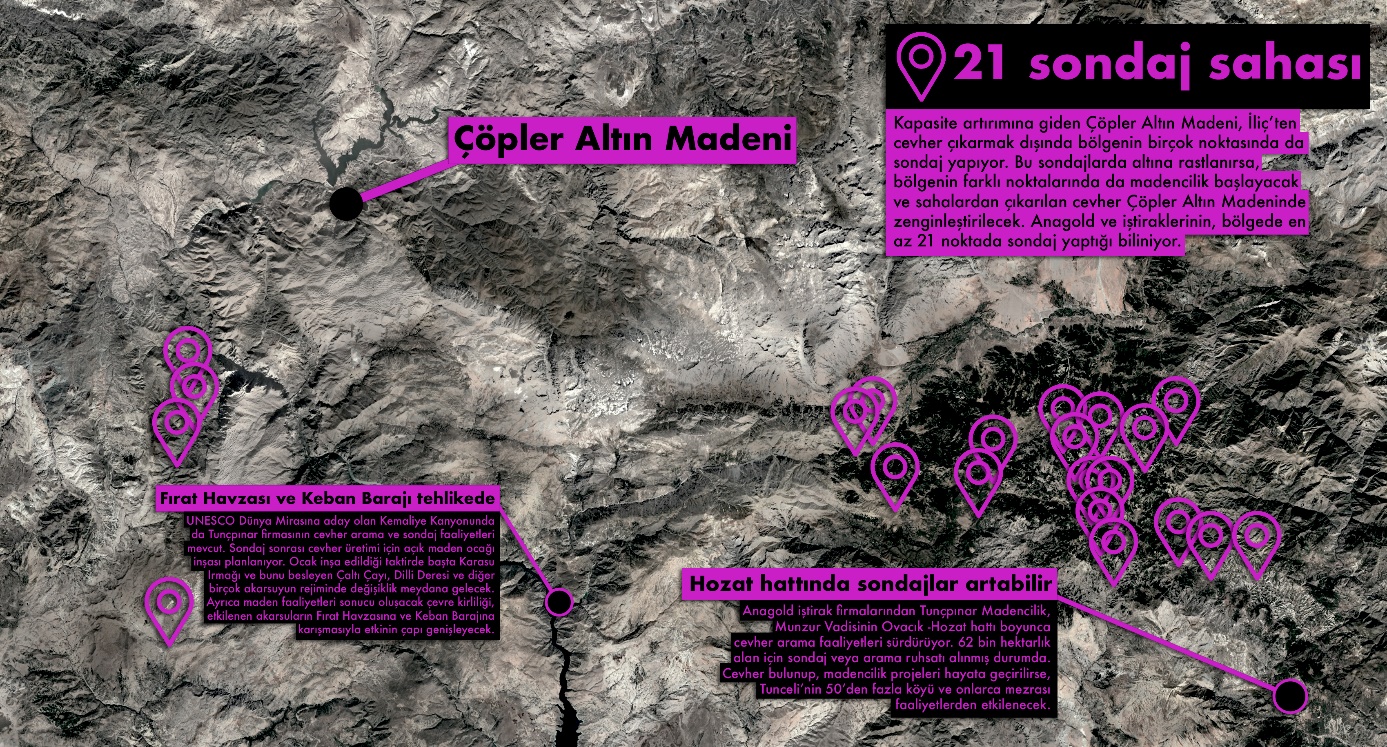

According to a statement published by Union of Turkish Chambers of Engineers and Architects (TMMOB) on July 27, 2019, the whole Munzur mountain range, which stretches for 60 kilometers in eastern part of Turkey, has been turned into a mine site. There are 145 mine projects that are currently being drafted in Tunceli province. Other projects are being developed in Kemaliye, Keban and Divriği districts. It is argued by many that Çöpler is the first step taken by mining companies to penetrate the region and expand their reach. There are allegations that ores to be extracted from Cevizlidere near Ovacık in Tunceli will be transported to Çöpler.

Considering the aggressive growth of the mine pit in the last 13 years, these allegations, if true, may mean that mining companies will be staying in the region for some time. Anagold currently holds mining licenses in 23 locations, as understood from the activities of its affiliates. It appears that most of these licenses were obtained to build limestone mines or stone quarries.

It is not a secret that ores extracted from Çakmaktepe complex, which is operated by Tunçpınar, an affiliate of Anagold (currently known as SSR Mining), are transported to and processed at Çöpler mine pit. This is public information published on the website of Tunçpınar company. Furthermore, Çakmaktepe complex is currently used for production of gold although it only holds a license for operating a stone quarry.

The official website SSR Mining contains a map on which 11 other gold ore sites are marked near Çöpler mine pit. A 25-kilometer-wide and 17-kilometer-long area has also been marked as licensed area. This means all villages in the area, including İliç district, are covered by the license. The investments and the statements of the Ministry of Energy demonstrate that the mining companies will continue their operations in this part of Turkey for some time. The borders of the mine have been expanded to reach Ortatepe and Bağıştaş in the west, Sabırlı, Yakuplu, Çaltı and hills of İliç district in the east, and Kabataş village in the south. There are also rumors that the whole district may be moved to different location.

In the periphery of the mine, which stretches all the way to Kemaliye and Ovacık, the mountains have been riddled with boring holes. SSR Mining, after expanding its mine every month, now sets its eyes on Kemaliye and Ovacık. This shows that companies are allowed to drill and search for gold anywhere they want.

Tailings impoundments that collect residual ores contaminated with cyanide only 300 meters away from Euphrates River already create a major concern. And now, ore to be transported from new mine pits in the region will be processed at Çöpler, which means these impoundments will reach their capacity earlier than expected. In other words, the likelihood and potential consequences of a disaster grow by the day.

* This article has been prepared in the scope of the “New Generation of Investigative Journalism Training Project” which is implemented by Media Research Association in cooperation with ICFJ (International Centre for Journalists).